Chat WhatsApp

Chat WhatsApphexup.service@gmail.com

Page d'accueil > Centre d'Information > Frequent fires in battery swapping cabinets, how to break the situation with open flame burning and hidden dangers?

At present, China's electric bicycle market stock is high, with 300 million electric bicycles in the country, and manufacturers produce 13 million per year, with booming production and sales. Electric bicycles have become an indispensable part of people's lives, penetrating into 80% of ordinary families. People's travel demand of 2-10 kilometers will not disappear, and this distance travel accounts for more than 30% of people's total travel demand. In other words, e-bikes are a market with high demand and many target users. The takeaway brother needs to charge and change the battery 2-3 times a day, and once every 3 days for the home, and the frequency of charging and swapping business is very high. At present, the battery swapping cabinet model has been proven to be the most direct business model to solve the problem of takeaway battery swapping and household battery swapping.

The location of the battery swap cabinet can be located all over the transportation hub, hot spots, high-end business districts, residential areas, schools, industrial parks, factories, and scenic spots. Ordinary people can use the self-service battery swap mode to cope with the anxiety of lack of electricity. At the same time, the battery swapping cabinet can also meet the high-frequency use of express delivery, takeaway, logistics and other industries. Therefore, the battery swap industry market is huge, and it is foreseeable that in the future, the battery swap market will continue to expand.

Recently, the fire incident of the battery swap cabinet has frequently made headlines, which has attracted widespread attention from all walks of life. These incidents not only pose a serious threat to the safety of people's lives and property, but also make people begin to re-examine the safety of battery swapping cabinets.

Source: Internet

On January 16 this year, a delivery rider posted information on the Black Cat complaint platform, saying that during the delivery process, the vehicle suddenly ran out of power and the adapter caught fire. Fortunately, the incident did not cause a fire. Not long after, on January 17, the lithium battery swap involved quickly responded and dealt with the matter through the Black Cat complaint platform. However, this is only the tip of the iceberg in the case of battery swapping cabinet fires.

Source: Internet

Another high-profile incident occurred in the battery swap cabinet of Yugu Technology. According to the prospectus of Yugu Technology, in May 2021, the battery swapping cabinet located in Fengshan Qiaozhi Street, Shangcheng District, Hangzhou was damaged due to BMS devices, resulting in overheating and smoke during charging. This incident once again highlights the hidden dangers of the battery swapping cabinet in terms of safety performance.

In addition, due to external factors such as electric vehicle fires, store fires, etc., Yugu Technology also had 4 accidents in which battery swapping cabinets and batteries were burned. These accidents not only caused economic losses, but also made people seriously question the safety performance of the battery swapping cabinet.

There are many types of combustible materials used inside the battery swapping cabinet, including: the top of the cabinet mains wire, the communication line inside the trunking, the battery in the cabinet, all kinds of air opening, etc. These combustible items are distributed in different parts of the battery swapping cabinet, among which the number of batteries in the cabinet is large, and the back-related wiring equipment is also many, the layout is dense, the space is narrow, and the fire hazard is the highest.

In this context, some enterprises have begun to pay attention to the safety performance of battery swapping cabinets and actively take measures to improve them. For example, some enterprises have strengthened the control of product quality and adopted more safe and reliable materials and designs, while some enterprises have strengthened user training and education to improve users' safety awareness and operation skills.

Source: hexup

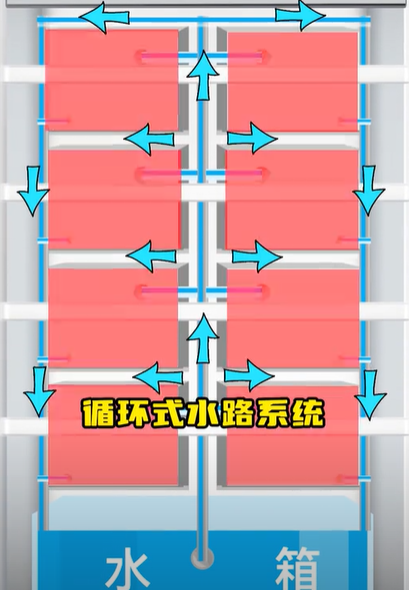

In the design and manufacturing process of the battery swapping cabinet on the sixth floor of the west, it strictly follows the safety standards and adopts advanced technology and materials to ensure the quality and safety performance of the products. For example, the interior of the warehouse adopts a submerged circulating water fire protection system, which can quickly submerge about half of the warehouse capacity in just one minute. In the event of an emergency with thermal runaway of the battery, the system is able to respond quickly and completely submerge the battery in water, thus effectively controlling the fire. After the battery is completely submerged in water, the water naturally flows back into the tank for recycling. Without any external interference, the warehouse has excellent sealing performance and ensures that there will be no water leakage. This design not only improves the safety of the warehouse, but also embodies the concept of efficient and environmentally friendly fire protection.

Source: hexup

In addition, the battery swap cabinet on the sixth floor of the west is also equipped with an intelligent monitoring system and safety protection devices, which can monitor the operation status of the equipment in real time, and find and deal with abnormal situations in time. In the event of a fire, the system will automatically trigger a fire extinguishing device to quickly extinguish the fire source and prevent the fire from spreading. These measures have greatly enhanced the safety performance of the battery swap cabinet on the sixth floor of the West Floor, providing users with a safer and more reliable battery swap service.

To sum up, the frequent occurrence of battery swap cabinet fires and the problems of open flame burning and hidden dangers need to be solved urgently. Only when enterprises strengthen the control of product quality and safety performance, and users improve their safety awareness and operation skills, can they jointly promote the healthy development of the battery swapping cabinet industry.

Voir plus

HEXUP Extends Shared Battery Lifespan in Swap Cabinets by 2 Years

Why Battery Swap Projects Take So Long and How HEXUP Solves It

Our Integrated Solutions for the Electric Two-Wheeler Industry

China's "Electric Donkey" Goes Global: Battery Swap Stations as the New Trend Under New National Standards

The Electric Two-Wheeler Wave Sweeping Across Africa: Kenya

Unlocking New Potential for battery swap stations: Reverse Power Supply for Worry-Free E-Mobility

Smart Battery Swapping Cabinets: New Opportunities and Challenges in the International Market

Revolutionizing the Battery Swapping Experience: HEXUP's Swapping Cabinets Enhance Efficient Collaboration

Battery Loss? No Worries! HEXUP's Battery Swapping System Builds a New Line of Defense for Battery Security

Battery Recycling Challenges? HEXUP's Intelligent Battery Swapping System Offers the Perfect Solution!